These Golf Clubs Can Be 3D Printed At Home!

Novel infills and designs in special products have entered the world of golf thanks to 3D printing. The end products, the speed of prototyping has affected the entire style process. Additionally, 3D printing allows for the modification of golf clubs for individual players and their styles.

In this article, we'll present a couple of inspiring golf club tasks that include 3D printing. There aren't any available 3D printable models for many of these projects, they still reveal off the capabilities of 3D printing. For each project, we'll discuss what printing strategies were used, the products, and more.

Cobra Golf: King Supersport-35 Putter

The first project on our list was conceived by Cobra Golf, a business that concentrates on innovative golf clubs and accessories. Cobra Golf partnered with the printer company HP, SIK Golf, and Parmatech to make a special limited edition putter club-- the King Supersport-35-- which cost about $400 per club.

The teaming up business used HP Metal Jet printers to print the club's components. This printing technology enables the high-volume production of high-grade metal parts, which showed beneficial for mass-producing golf clubs.

The golf club's design consists of a 3D printed steel body. A 3D printed lattice structure was included into the design in order to optimize the distribution of the putter's weight. Even more, CNC milling was utilized on the head for cosmetic surfaces. Another unique function of the King club is an aluminum descending-loft style for the face of the putter, a style established and patented by SIK Golf for a consistently precise roll.

Cobra's use of 3D printing in this style permitted the business to explore the capacity of 3D printing in the golf industry, especially the fabrication of specially-made and lightweight clubs. According to Cobra, 3D printing made the manufacturing process faster and also boosted quality and precision. They were able to quickly prototype and test designs, enabling them to accomplish a final product quicker than traditional manufacturing and prototyping approaches.

Krone Golf: KD-1

Krone Golf was a golf innovation company that established the KD-1, a specially-manufactured and partially 3D printed golf driver club. To create the KD-1, Krone partnered with the CRP Group, an Italian company that utilizes 3D printing, to name a few technologies, to help business and organizations perform jobs.

Given that the launch of their golf club task in 2016, Krone Golf has actually gone radio-silent, and their website no longer exists. For this reason, we presume that they went out of business, however their golf club is still an excellent example of the power of 3D printing.

Krone wished to demonstrate how additive (3D printing) and subtractive (CNC milling) manufacturing could make an excellent golf club. The company's previous production approaches were labor-intensive and did not yield dimensionally accurate items. Also, the techniques did not enable the simple personalization of parts.

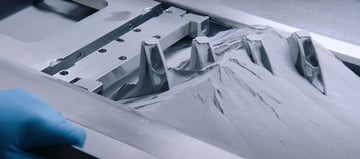

The use of 3D printing and CNC milling in creating the KD-1 made the production process much easier and improved the quality of the item. For the body of the head, Krone Golf utilized SLS 3D printing and an unique material known as Windform SP, which is a strong carbon composite product that yields dimensionally-accurate parts.

The driver's front face is CNC machined from a titanium alloy, that makes the face strong and light-weight. It also possesses a lattice structure, which lowers weight while mainly preserving strength.

On top of all that, there's also a brass CNC-milled clip component that holds the other pieces together. The brass part really has particular holes for screws to grip or bind the other elements.

After production, Krone found that integrating 3D printed and CNC-machined parts yielded an excellent golf club with numerous advantages over traditionally-manufactured motorists. Swinging speeds increased due to the lightweight style, and the parts were more accurate than those made with injection molding or other standard production approaches. The business experienced enhanced versatility in the style procedure: Engineers were able to fine-tune the driver's design to enhance the club without making a brand-new mold like with standard production techniques.

TaylorMade Golf: SIM Fairway

TaylorMade Golf is another professional golf business that makes clubs of all types and other golf devices, and they used 3D printing to model their brand-new items quicker. As the company established among the very first metal head chauffeurs, it's not a surprise that they're continuing to innovate, in this case by using 3D printing to the style of their golf clubs.

While the company didn't in fact 3D print the last club, they utilized the technology to best the design and enhance specific qualities. To do this, TaylorMade partnered with FormLabs, a producer of professional-grade SLA 3D printers, to develop exact prototypes during the design of their dependable SIM Fairway golf club.

TaylorMade Golf wanted their SIM Fairway club to have actually enhanced features, consisting of a lower center of mass, better turf traction, and a more "flexible" face, to name a few improvements. In addition, TaylorMade hoped to build on their present approach for users to add weights to the club, in order to make the weight change process for every player simpler.

The company's designers and engineers started designing their SIM Fairway club in 2D and after that used 3D printing to establish models of the CAD designs to make sure that their expectations were met. TaylorMade used FormLabs' SLA printers, which use a laser to bond resin particles together in selective locations to form the wanted part. By making use of 3D printing for rapid prototyping, TaylorMade was able to rapidly evaluate new shapes for the weighted inserts to finalize a better style.

Callaway Golf: Odyssey Putter

Joining the list of companies that utilized 3D printing to upgrade their golf club is Callaway Golf, a well-known business whose line of Odyssey Putters is among the top-selling clubs on the marketplace. Callaway Golf partnered with GE Additive to redesign one of Callaway Golf's putter heads, the Odyssey R-Ball Prototype.

Their original design of the Odyssey R-Ball worked terrific. Still, Callaway Golf wanted to alter the acoustic signature-- the sound that it makes when struck-- without adjusting the already-effective products and design. Their option was to include internal geometries, essentially infill, which is only possible with 3D printing. GE Additive's group also designed assistances for overhangs in the putter head's design in addition to for thermal tensions, which likely assisted to prevent distortion by dissipating excess heat.

Callaway appears quite devoted to checking out the style and manufacturing advantages of additive production. In addition to their work with GE Additive, they partnered with Titomic, an Australian company concentrating on metal additive manufacturing. Their patented Titomic Kinetic Fusion technology is marketed as "the world's biggest & fastest metal 3D additive production technology."