Availability: 5 in stock

Estimated Arrival: Between Apr 16 and Apr 21. *ETA to Canada Only

Shipping & Returns: Free Shipping Canada wide for All Orders Over $99!

CREATBOT D1000 Large Scale Industrial 3D Printer

CreatBot D1000 sets a new standard in additive manufacturing and extends the capabilities of large-scale Industrial 3D Printers, it brings the possibility to bring high-quality products while reducing manufacturing times and costs for companies. CreatBot F1000 Comes equipped with a new smart dual extruder kit, an enclosed heated chamber, automatic leveling systems, and camera control to manufacture large, high-quality prints.

With a Fast Heating Platform and Hot-Chamber this high resolution, large-print workhorse produces incredible results and can print with ABS,PLA, Carbon Fiber, PETG, Nylon, PC, Flexible, and much more high-performance engineering-grade materials.

CreatBot D1000 will be your best choice if you are looking for an affordable top-quality large-scale manufacturing workhorse for your industry.

Features Summary-

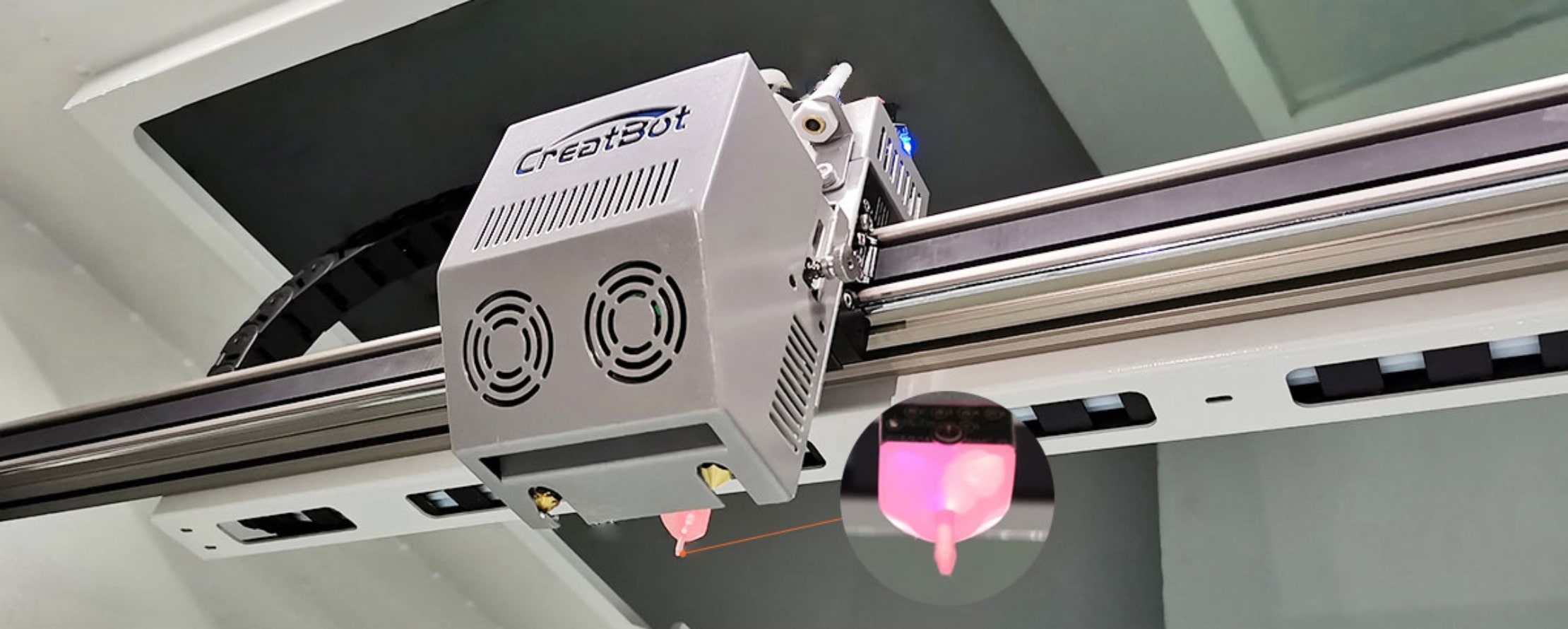

Smart Dual-Extruder System

Embedded with new smart dual extruders and a high-temperature hot-end capable of reaching up to 420°C, It is able to print with PLA, ABS, PC, Nylon, Carbon Fiber, Flexible, and more high-performance materials for direct application.

The Dual Hot-End is very easy to maintain and very affordable to replace.

High Precision Printing

The extensive research and development of CREATBOT D1000 3D Printer, Extruder feeding systems, and guide rails allow a very high accuracy of 0.01MM while maintaining printing speed at 200MM/S without blockage.

Huge Build Size 1000x1000x1000mm

Made with large-scale manufacturing in mind, Creatbot D1000 allows you to print huge industrial-sized models hassle-free without compromising on quality.

Stable and Sturdy Build

The whole-steel body ensures stability when printing and greatly extends the usage period. The structure makes CreatBot D1000 a sustainable, efficient and reliant workhorse. The first batch of CreatBot 3D Printers have been working for over 10 years and more than 30000 work hours.

Fully enclosed- Hot Chamber & Filament Drying Room

Fully Enclosed Chamber blocks all external interference and reduces noise.

The Hot Chamber can provide constant room temperature as well so the model won’t deform. Acrylic Doors can be opened to remove prints conveniently.

Power Outage Save & Filament Detection

The printer will protect your project from a sudden power outage by memorizing the current position, saving print data, lowering the working platform, and withdrawing filament.

It will resume printing after powering on and will avoid invalid printing by stopping print and warning when filament runs out.

Camera Control

Camera control technology allows you to completely control the printing process on a remote app making it a very useful feature on large models and long print times.

"Better quality than German-made, much cheaper than Europe-price" -- Roland Teo, CEO of Props Factory Ltd.

PRINTING VIDEO

Technical Specs

| Printing | |

| Print Technology | Fused Deposition Modeling |

| Build Volume | 1000*1000*1000mm |

| Number of Nozzles | Double |

| Resolution | 0.1 mm |

| Layer Resolution | 0.05 mm |

| Filament Diameter | 1.75 mm |

| Filament Compatibility | ABS,PLA,Carbon Fiber,PETG,Nylon,PC,etc. |

| Nozzle Diameter | 1.0 mm(0.4~1.5 mm) |

| Print File Type | STL, OBJ, AMF, Gcode |

| Temperature | |

| Max. Nozzle Temperature | 420 ℃ |

| Max. Bed Temperature | 100 ℃ |

| Hot Chamber Temperature | 60 ℃ |

| Filament Dry Room Temperature | 45 ℃/65 ℃ |

| Mechanical | |

| Construction | Power-Coated Steel, Aluminum Casting for Motion Components, POM |

| Build Plate | Glass Ceramic Panel |

| Build Plate Leveling | Automatic |

| Extruder | Smart Dual Extruders |

| Stepper Motors | 1.8° Step Angle with 1/16 Micro-stepping |

| X Y Positioning Precision | 0.011 mm |

| Z Positioning Precision | 0.002 5 mm |

| Software | |

| Software Bundle | CreatWare, Simplify 3D, Cura, Slice 3r, etc |

| Supported File Types | STL,OBJ,Gcode,AMF |

| Operating Systems | Win7/8/10, MacOS |

| Special Function | |

| Outage Restored | Save data when power is off |

| Filament Detection | Pause printing when filament run out |

| Automatic Shut-down | Turn off the power automatically when printing is complete |

| Camera control | Camera remote monitoring and real-time control of the printing process |

| Speed | |

| Best Printing speed | 60 mm/s |

| Max. Printing speed | 120 mm/s |

| Electrical | |

| Power Requirements | 220~240 V, 50~60 Hz |

| Screen | 9.7-inch full color touch screen independent operating system (multi-language) |

| Max. Power | 4000W |

| Storage Media | U Disk |

| Connectivity | USB |

HIGH PRINT TEMPERATURE UP TO 420°C-

CreatBot D1000 is embedded with new smart dual extruders and a high hot-end temperature of 420°C.

It is able to print with PLA,ABS,PC,Nylon, Carbon Fiber, Flexible and more high performance materials for direct application.

The Dual Hot-End is very easy to maintain and very affordable to replace.

HIGH PRECISION PRINTING-

CreatBot's exclusive research and development of CREATBOT D1000 3D Printer, Extruder feeding systems and guide rails allows high-speed printing, very high accuracy that reaches 0.01MM while printing at 200MM/S without blockage.

ACCURATE LINEAR GUIDE RAIL-

The accuracy of the linear rail structure allows for higher reach than other ordinary optical axis printers, This structure offers accurate filament feeding so the print remains perfect while being quickly printed.

STABILITY-

The whole-steel body does not only ensure the stability when printing but also greatly extends the usage period. The optimization and construction of the overall structure ensures a sustainable and efficient operation. The first batch of CreatBot 3D Printers have been working for 9 years and more than 30000 hours.

HUGE BUILD SIZE -

CREATBOT D1000 INDUSTRIAL 3D PRINTER has a build size of 1000x1000x1000mm , giving you a huge build volume combined with exceptional print quality. Now you can make larger 3D models without compromising on the quality of your end products.

POWER OUTAGE RESTORE & FILAMENT DETECTION-

The printer will protect your project from a sudden power outage by memorizing the current position, saving print data, lowering the working platform and withdrawing filament if the power suddenly turns off.

It will resume printing after powering on and will avoid invalid printing by stopping print and warning when filament runs out.

FULLY ENCLOSED- HOT CHAMBER + FILAMENT DRYING ROOM

Fully Enclosed Chamber blocks all external interference and reduces noise.

The Hot Chamber can provide constant room temperature as well so the model won’t deform when printing. Acrylic Doors can be opened to remove prints conveniently.

CAMERA CONTROL TECHNOLOGY-

Control the printing process with a remotely via app

AUTO LEVELING PLATFORM PRO

Use of 64 points through the BL-Touch probe and an Intelligent Z Axis system that saves the platform level data and allows fully automated leveling during the printing process.

QUESTIONS & ANSWERS

Have a Question?

Be the first to ask a question about this.